Premium Numbing Cream Wholesale Your Tattoo Solution!

With over 5,000 expertly crafted formulas, Hilook helps elevate your brand with custom private label services tailored to your vision. Tailor-made tattoo care products and a complete product line designed to meet your unique needs. Bring personalized care and superior results to your clients.

문신 마비 라인

다양한 문신 마비 라인 제공, 우리 제품은 전문 문신 예술가의 요구를 충족시킵니다., 브랜드 소유자, 전자상거래 상점, 그리고 스타트업 기업. 고객의 편안함과 만족을 보장하는 혁신적인 솔루션으로 통증 없는 문신 세션을 달성하세요..

문신 전 통증 문신 마비 크림

전신 마비 문신 스프레이

통증 완화 오래 지속되는 문신 눈썹 젤

통증을 오래 지속되는 문신 눈썹 젤 감소

문의하기

*We respect your confidentiality and all information are protected.

How Can We Help with Private Label Solution

원하는 항목을 선택하세요

Personalize your brand or select the best products with our exoert guidance.

제품 샘플링

Our team streamlines product sampling to guide you conveniently in finalizing your manufacturing list.

제품 디자인 마무리

Elevate your brand with our customized packaging design services not limited to logo, formulas.

판매 후 지원

Our experts provide ongoing guidance and resources for effective marketing and sales in the tattoo market.

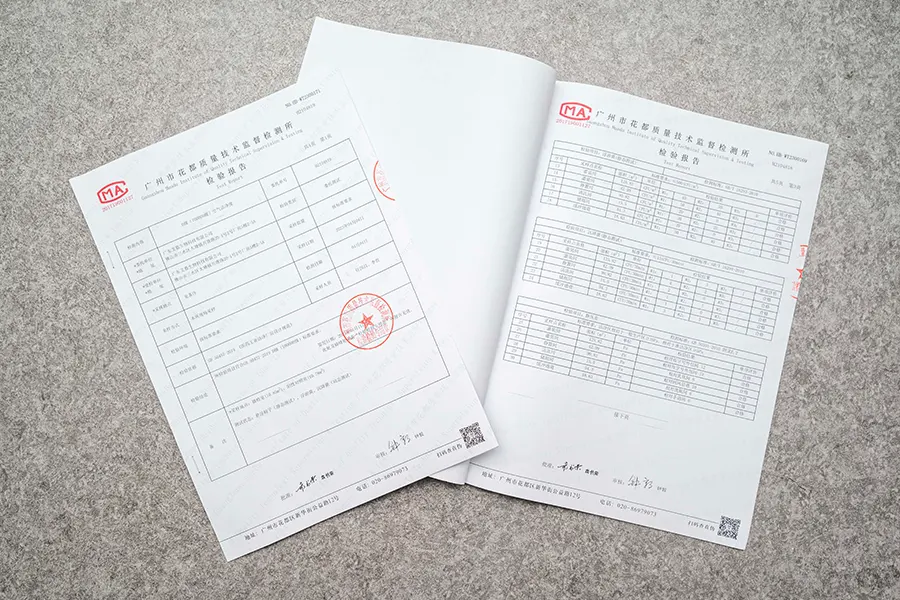

Safe & Effective Formula

순수 천연 식물과 효과적인 문신 관리 제품을 살펴보세요, 귀하의 문신 사업을 향상시키기 위해 고안되었습니다.. 세심하게 제작된 제제는 고객의 안전과 마음의 평화를 최우선으로 생각하면서 최적의 결과를 보장합니다..

| 재료 | 효과 | |

| 문신 마비 크림 | 20% 활성 성분 | 고통을 재현, 스무딩 |

| 문신 마비 스프레이 | 아르기닌, 알란토인 | 빠르고 효과적인 마비 |

문신을 제외한 더 많은 응용 프로그램

당사의 제품은 다양한 요구 사항을 충족하는 안전하고 다양한 포뮬러를 특징으로 합니다., 화상 및 화상을 포함하여. 향상된 사용자 웰빙을 염두에 두고, 우리의 제제는 광범위한 응용 분야를 제공합니다, 개인 관리에 대한 고조된 감각을 촉진합니다..

타투 / 눈썹 라인을 그려주세요 / 불타다 / 뎀 / 모기에 물리다 / 가려움증과 불편함

왜 Hilook인가?

힐룩에서, 고객 만족이 최우선입니다. 우리는 귀하의 비즈니스에 실질적인 이점을 제공하는 고품질 솔루션을 제공하기 위해 최선을 다하고 있습니다..

고품질 & 다양한 제품

고등급 원료

아르 자형&D 능력

최첨단 생산 설비

High-standard & Precise Manufacturing Process

탁월한 생산 프로세스를 발견하십시오, 우수한 품질과 효율성을 제공합니다. 원료에서 고급 기술에 이르기까지, 문신 관리를위한 제조 능력의 강점을 경험하십시오..

1. Pre-manufacturing From Storage to Measurement

● Material Supply Chain:

우리의 모든 포뮬러는 가장 높은 기준에 따라 개발되었습니다. 이미 테스트를 거쳐 법적 승인을 받았습니다..

● 원료 저장:

우리는 포장 디자인 서비스를 제공하고 비용 절감형 패키지 공급업체와 협력합니다., 당신을 위해 다양한 옵션을 제공합니다..

● 포장 재료 저장:

우리는 포장 디자인 서비스를 제공하고 비용 절감형 패키지 공급업체와 협력합니다., 당신을 위해 다양한 옵션을 제공합니다..

2. 생산 전 재료 테스트

● Raw material inspection

This includes appearance checks such as color, 맛, 및 감각 평가, 오염을 방지하기위한 미생물 검사와 함께. 추가적으로, 다양한 테스트 기계가 활용되어 성분 콘텐츠에 대한 질적 검사를 수행합니다., 색상, 점도, 경도, 그리고 더.

● Packaging material inspection

Primarily focused on examining connection status and appearance of connection parts which involves checking size, 색상, 그리고 표면 모양. 스프링클러 포장 재료는 스프링클러 성능을위한 테스트를 거친다, 완전한 액체 용량, 내구성, 그리고 스트리핑. 테스트는 생산 중 최적의 상태를 보장하기 위해 엄격합니다., 누출 위험을 최소화합니다.

3. 원료 측정

제품 내용을 생산하기 위해, 원료는 각 제품의 특성에 따라 측정해야합니다.. 원자재의 측정은 컴퓨터 시스템에 의해 제어됩니다..

원자재의 유형과 함량은 제어 프로그램에 의해 정확하게 측정됩니다., 결과는 데이터 뱅크에 기록됩니다.

자세한 측정 정보는 측정 후 부착 된 바 코드로 작성됩니다., 원자재 관리에 대한 자세한 정보를 기록하기 위해.

4. 제조하는 동안

바코드 확인 후, 생산 공정을위한 제조 냄비에 재료가 추가됩니다., 여기에는 해산이 포함됩니다, 유화, 분산, 저장, 냉각, 여과법, 그리고 더. 이것은 다양한 화장품에 적용됩니다, 나노 제품 포함.

게다가, 제조 공정에는 입자를 나노 스케일 입자로 형질 전환하는 것이 포함됩니다, 통제 절차를 통해 고품질 제품 보장.

5. 기계 충전

순도를 유지합니다, 가스 청소 먼지 수집기는 드라이 클리닝 공급 컨테이너에 사용됩니다.. 센서가있는 자동화 된 시스템은 입자를 효율적으로 캡처합니다, 안전한 처분을 위해 필터링. 수동 장치는 청소를위한 실습 접근 방식을 제공합니다. 목표는 외국 물질을 제거하고 물질적 무결성을 보존하는 것입니다..

6. 미생물 검출

미생물 검사는 제품 품질을 철저히 보장하는 기본 단계입니다.. 원자재/제품에 대해서만 수행되지는 않습니다.

고객이 사용할 때 발생할 수있는 문제를 고려/해결하기 위해 생산/포장 공장의 공기 및 인체의 미생물을 관리조차도. 고객 신뢰를 향상시킵니다.

Microbiological inspection mainly includes the following stages, 이러한 검사를 통해 배송 된 제품은 자격을 갖춘 제품이 될 것입니다 (재료/목차/제품).

7. 완성 된 제품 테스트

완성 및 반제품의 품질을 평가합니다, our appearance inspectors evaluate aspects such as color, 향기, 유용성, and design from the consumer’s perspective.

제품 완료 후, QC conducts sampling inspection based on production order requirements and GB2828 acceptance standards. 자격을 갖춘 제품은 봉인되어 스토리지를 위해 릴리스됩니다.

회사의 배달 관리 시스템에 따르면, products must pass both physical and chemical tests as well as meet appearance inspection criteria before being approved for delivery.

간편한 단계로 사용자 정의

1.귀하의 요구 사항을 보내

2.무료 샘플 확인

3.포장 디자인

4.제품생산

5.품질 관리

6.판매 후 지원

Hear from Our Partners

As a leading tattoo numbing company and manufacturer, 우리는 뛰어난 자사 브랜드 솔루션을 성공적으로 제공했습니다. 1,000 전세계 기업.

많이

티나

마리 브라운

조롱

We Collaborate with People and Brands;

Let’s Build Something Great Together.

- info@hilooktattoo.com

- +86 13326683584

- +86 18307535973

- 301, 건물 1, 윈산 크리에이티브 컴파운드, 아니요. 2, 둥핑 동컹 거리, 용핑 거리, 바이윈구, 광저우

저작권 © 2023, 힐룩. 판권 소유.